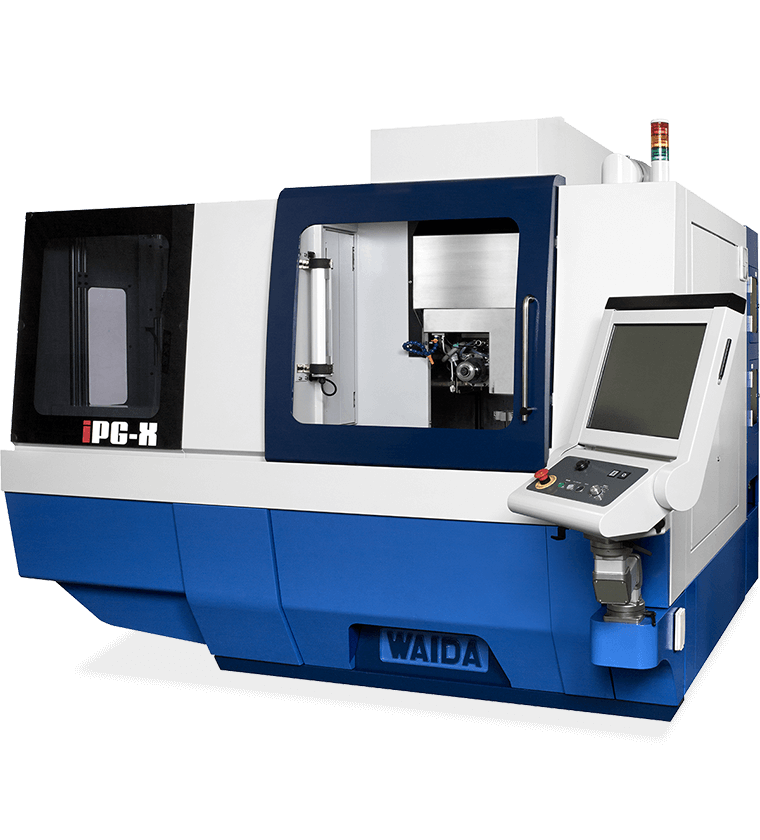

An intelligent profile grinder that enables fully automatic compensation finishing of high-precision mold parts.

| Usage |

High-precision mold parts (punch & die) |

| material |

Carbide |

Benefit

- Equipped with an original interactive program (iPG-Lab) that follows the operability of the SPG-W series

- Various functions (CAM, grinding wheel measurement, thermal displacement measurement, image processing) enable fully automatic correction finishing.

- Simple high-rigidity structure with a total of 4-axis configuration of 3 linear linear motors and 1 rotating DD motor

- Product measurement with report function by high-precision image processing

- Can be equipped with ATC/AWC that enables automatic processing of different types of punches and dies

- In addition to high-precision uniform taper processing of the die, cutting edge straight processing is also possible.

- Equipped with grinding wheel and workpiece measurement with a digital camera and automatic correction function

- Profile machining is fully automated by installing an automatic tool changer (ATC) and an automatic work changer (AWC).

- fully-covered design support for safety and ease of use

Download brochure PDF

Works

Back to product information list